Metal Foundry: How It Enhances Vessel Performance

Wiki Article

The Advantages of Functioning With a Full-Service Aluminum Shop Companion

Working together with a full-service aluminum foundry companion presents unique advantages for businesses seeking effectiveness and top quality. These partnerships improve design versatility and enhance production procedures. Additionally, they supply access to innovative innovations and skilled competence. This harmony not only boosts high quality control yet also promotes flexibility in a hectic market. Recognizing the complete spectrum of these advantages can substantially influence a company's success in today's affordable landscape. What exists past these preliminary advantages?Improved Design and Prototyping Capabilities

While numerous makers face limitations in style versatility, partnering with a full-service aluminum shop significantly improves the design and prototyping procedure. Such partnerships assist in accessibility to innovative modern technologies and expertise, allowing for even more cutting-edge styles that could or else be unattainable. The factory's abilities frequently include computer-aided layout (CAD) and fast prototyping, which enable makers to imagine and fine-tune their concepts prior to final production.Furthermore, these shops can supply valuable responses throughout the style stage, helping to recognize possible issues beforehand and recommending alterations that improve manufacturability. This cooperation minimizes the threat of expensive errors and lowers time-to-market for new items. A full-service shop can accommodate a vast variety of light weight aluminum alloys, enabling developers to pick products that ideal fit their particular efficiency requirements. Overall, this partnership cultivates a much more responsive and nimble style process, ultimately benefiting the end item.

Streamlined Production Processes

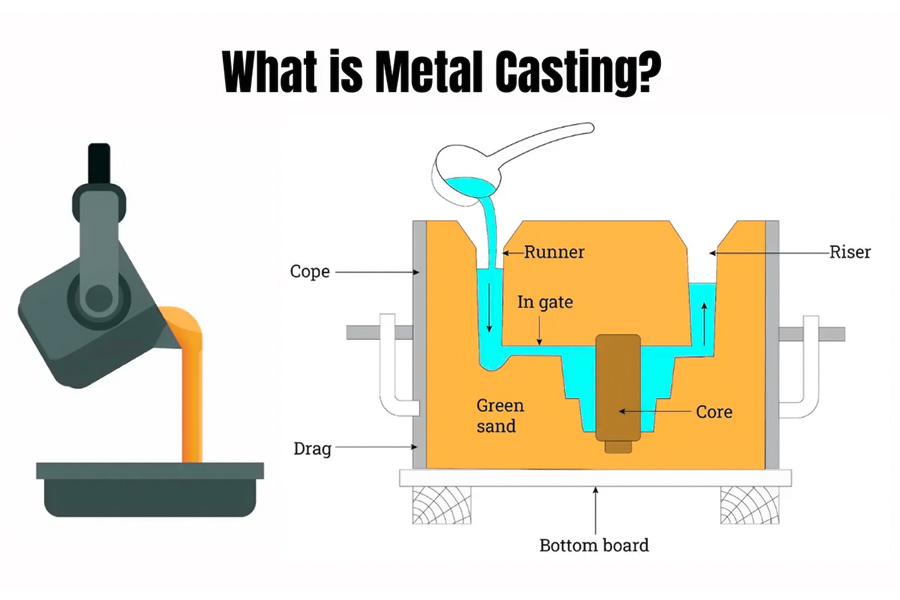

Collective style efforts with a full-service light weight aluminum factory not just enhance prototyping however likewise result in streamlined production procedures. By incorporating layout and production from the start, these collaborations enable the identification and elimination of prospective bottlenecks early in the workflow. With access to experienced personnel and innovative technologies, shops can optimize casting methods and improve production strategies, resulting in shorter preparation and boosted performance.A full-service factory offers considerable solutions, including tooling, finishing, and high quality guarantee, all under one roofing. This debt consolidation minimizes the demand for several distributors, minimizing communication delays and imbalances. Metal Casting. In addition, the constant responses loop developed between style and manufacturing groups ensures that any type of problems are quickly attended to, keeping a smooth functional circulation. Inevitably, the synergy produced through these joint initiatives not just enhances product quality yet also accelerates time-to-market, providing substantial benefits in today's affordable landscape

Cost-Effectiveness and Resource Optimization

Cost-effectiveness and source optimization are essential factors when partnering with a full-service light weight aluminum shop. By lowering production expenses and guaranteeing reliable resource allotment, companies can accomplish significant savings while keeping top quality. Structured manufacturing procedures even more boost these benefits, making cooperation with a seasoned shop partner a strategic option.Reduced Manufacturing Expenses

A collaboration with a full-service light weight aluminum factory can substantially minimize manufacturing costs, making it an appealing alternative for suppliers. Metal Casting. By leveraging customized devices and proficiency, these factories simplify production processes, lessening waste and ineffectiveness. This brings about lower functional expenses and makes it possible for manufacturers to provide affordable pricing in the market. Moreover, full-service foundries frequently offer bulk investing in alternatives for basic materials, which can considerably reduce product prices. Their capacity to deal with various services internal, such as spreading, machining, and finishing, gets rid of the need for multiple suppliers, minimizing overhead expenses. Inevitably, the assimilation of services and maximized manufacturing techniques add to a more economical production procedure, allowing firms to concentrate on development and technology while maintaining profitabilityReliable Resource Appropriation

Making the most of resource allotment is key to boosting total manufacturing effectiveness. A full-service light weight aluminum shop companion supplies useful expertise in optimizing the use of products, labor, and equipment, making sure that sources are used properly. By leveraging experienced employees and sophisticated innovations, these foundries reduce waste and decrease excess stock, bring about significant cost savings. In addition, their ability to adapt to altering job needs allows for better responsiveness and resource monitoring. This tactical allowance not just improves manufacturing timelines however also enhances product top quality by making sure that the right sources are used at the ideal phases of manufacturing. Because of this, firms can attain an extra lasting procedure while keeping affordable prices and meeting consumer needs effectively.Streamlined Production Processes

Streamlined manufacturing procedures play an important duty in enhancing both cost-effectiveness and resource optimization within aluminum factories. By incorporating lean approaches and advanced technologies, full-service shops decrease waste and boost manufacturing effectiveness. This method allows for faster turn-around times, which reduces labor costs and raises result. Additionally, a well-organized workflow warranties that materials are made use of deliberately, therefore reducing overall manufacturing costs.Standard treatments help with much better quality control, decreasing the probability of problems and revamp. As a result, clients take advantage of consistent item quality while keeping budgetary constraints. Eventually, partnering with a full-service aluminum foundry that prioritizes structured production processes can meaningfully enhance a company's functional efficiency and earnings in today's open market.

Access to Advanced Technologies and Expertise

Accessibility to innovative innovations and proficiency is a considerable benefit of partnering with a full-service aluminum factory. Utilizing click here for more info advanced production procedures enhances production effectiveness and item quality. Additionally, a knowledgeable technical workforce assurances that jobs are performed with accuracy and technology.Cutting-Edge Production Processes

A plethora of markets take advantage of the advanced manufacturing processes used by a full-service light weight aluminum foundry partner. These sophisticated methods enhance production efficiency and precision, permitting for the development of intricate light weight aluminum elements tailored to specific applications. Innovations such as additive manufacturing and accuracy casting make it possible for shops to lower waste and lessen lead times, guaranteeing a quicker turnaround for clients. Additionally, the combination of automation and digital innovations simplifies procedures, improving general efficiency. By making use of advanced devices and methodologies, foundries can consistently deliver high-grade products that satisfy stringent industry standards. This dedication to welcoming the current innovations settings full-service light weight aluminum factory companions as leaders out there, giving considerable advantages to their customers throughout numerous markets.Knowledgeable Technical Workforce

While many sectors deal with obstacles in finding proficient labor, full-service aluminum shop partners succeed by utilizing a highly educated technological workforce that excels in innovative modern technologies and sector ideal techniques. This workforce is experienced at utilizing cutting edge equipment and software program, making sure that production procedures are reliable and accurate. Their knowledge enables for the smooth combination of cutting-edge techniques, leading to premium item top quality and reduced lead times. Furthermore, continual training and advancement programs are applied to maintain the workforce upgraded on the most up to date improvements in light weight aluminum casting and handling. By leveraging this knowledgeable labor, foundries can respond efficiently to intricate project demands, eventually supplying customers with trusted services tailored to their details needs.

Enhanced Quality Control and Guarantee

Quality assurance and guarantee stand as critical elements in the operations of a full-service aluminum foundry. These processes guarantee that the products manufactured meet stringent sector criteria and customer requirements. A devoted high quality administration system, typically incorporated throughout the manufacturing phases, enables constant monitoring and evaluation of materials and techniques.Full-service aluminum foundries utilize sophisticated testing techniques, consisting of non-destructive testing and metallurgical evaluation, to recognize potential issues early in the manufacturing process. This proactive method mitigates the threat of expensive rework and warranties that ended up products are trusted and durable. Furthermore, a society of high quality within the workforce boosts responsibility and fosters a dedication to quality.

Flexibility and Flexibility to Market Modifications

Adapting to market modifications is vital for full-service aluminum factories, enabling them to respond quickly to evolving client demands and market fads. An adaptable factory can change production timetables, change styles, and apply new modern technologies rapidly, guaranteeing that customers receive prompt and appropriate solutions. This versatility not only enhances consumer satisfaction but also cultivates long-lasting collaborations.A full-service light weight aluminum shop's ability to pivot in reaction to market variations allows services find this to exploit on emerging opportunities. By staying in harmony with shifts in demand, such as an upsurge in sustainable items or innovations in light-weight products, these shops can introduce and improve their offerings appropriately. This responsiveness is a critical property in an affordable landscape, as it helps clients minimize preparations and handle prices properly. Ultimately, flexibility and adaptability setting full-service light weight aluminum factories as indispensable partners in navigating the intricacies of the modern-day market.

Regularly Asked Questions

What Kinds Of Aluminum Alloys Do Full-Service Shops Typically Use?

Full-service factories normally make use of numerous light weight aluminum alloys, consisting of 1xxx, 2xxx, 3xxx, 4xxx, 6xxx, 7xxx, and 5xxx series. Each alloy serves specific applications, providing different residential properties like stamina, corrosion resistance, and weldability tailored to sector requirements.Exactly How Can I Establish the most effective Foundry Partner for My Task?

To identify the best factory companion, one should evaluate their experience, capabilities, high quality control processes, customer testimonials, and responsiveness. Contrasting quotes and going to facilities can also offer understandings right into their dependability and knowledge.

What Is the Lead Time for Customized Light Weight Aluminum Castings?

Do Full-Service Foundries Offer Design Appointment Services?

Yes, full-service foundries generally offer style assessment solutions. This help helps clients refine their principles, ensuring optimal capability and manufacturability, while likewise attending to any technological obstacles that may arise during the light weight aluminum casting process.What Industries Generally Take Advantage Of Light Weight Aluminum Shop Partnerships?

Industries such as vehicle, aerospace, building and construction, and electronics generally take advantage of aluminum factory collaborations. These markets depend on aluminum's lightweight and long lasting residential or commercial properties for producing elements, boosting efficiency, and conference stringent market criteria efficiently.While several makers deal with restrictions in style versatility, partnering with a full-service aluminum shop considerably improves the style and prototyping procedure. Collaborative layout initiatives with a full-service light weight aluminum shop not only improve prototyping yet likewise lead to structured manufacturing procedures. A collaboration with a full-service aluminum foundry can significantly decrease production costs, making it an appealing option for manufacturers. A wide range of industries profit from the sophisticated production processes supplied by a full-service light weight aluminum foundry companion. Full-service light weight aluminum shops use advanced testing techniques, consisting of non-destructive testing and metallurgical evaluation, to recognize possible flaws early in the manufacturing procedure.

Report this wiki page